| Parameter | Description |

| Material | Iron and Steel |

| Brand | INPA |

| Feature | 100% automatic storage system, robot application and conveyor belts allow the process of importing and exporting goods to take place quickly, safely and most accurately. |

ASRS racking or automatic storage and retrieval system is the abbreviation of the English phrase: Automated storage and retrieval system. A storage solution that supports fully automated control, retrieval and rotation of goods. To learn more about the operating principles of this shelf line, INPA invites readers to read the article below with us!

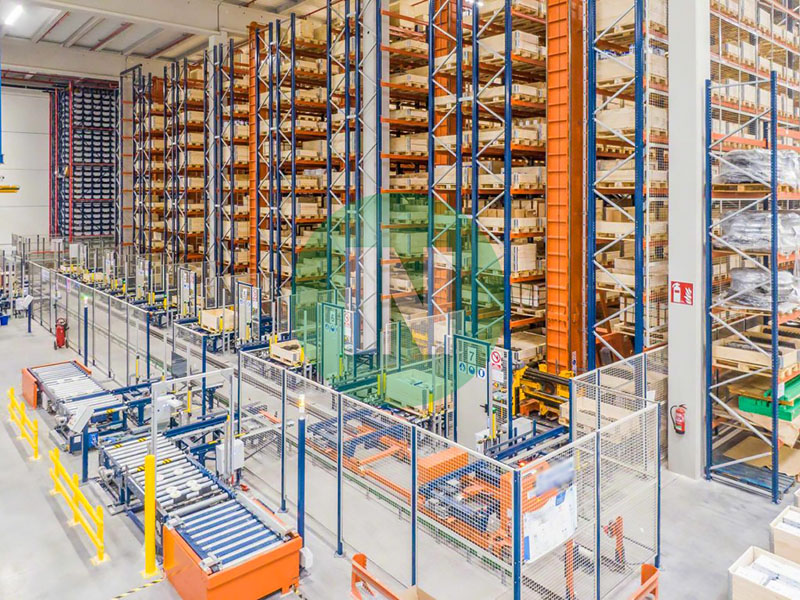

At its core, ASRS is a heavy duty racking system managed through computers and automation software. To facilitate optimal smart storage and retrieval processes. Operations take place completely automatically through a modern robot racking system and smart software.

ASRS racking operates according to the following principle:

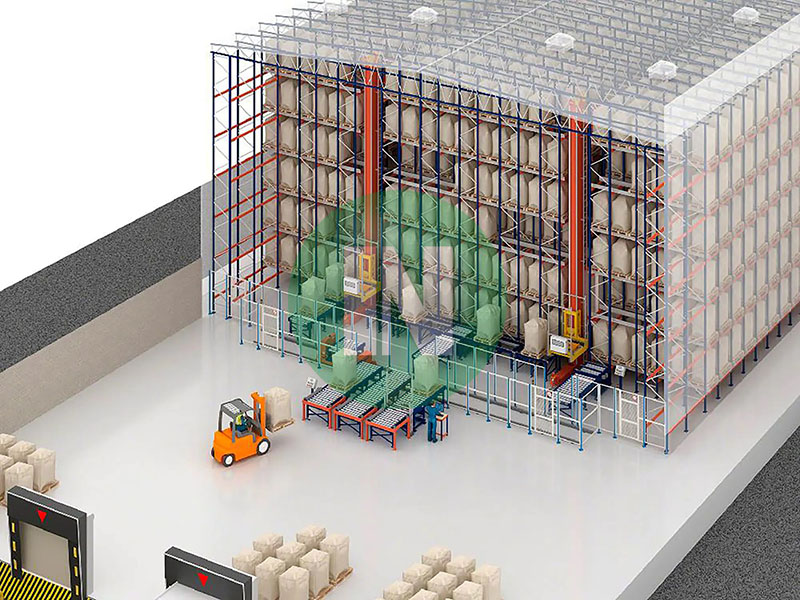

Instead of forklifts entering the rows of shelves to load and unload goods, with the ASRS system, robots and ASRS cranes will access and move each pallet position accurately. This process is carried out on the basis of most types of pallets, but with the usual specifications of 1m x 1.1m, 1m x 1.2m, 1.1m x 1.1.m, 1.2m x x1.2m.

When importing goods: After receiving the pallet and the position command notifies the location of the pallet, the robot is moved along the aisles by the crane to arrange the storage and loading process smoothly. The loading process continues when the Robot runs on the rack rails and is responsible for transporting pallet positions to the rack rails until they are filled with goods.

When exporting goods: After the robots receive orders from the device or control center, they will accurately approach each pallet location. Proceed to disassemble and take the pallet out to the aisle, where the crane is waiting to receive the pallet to take the goods out of the system. As soon as the pallet is brought to the top of the shelf row, it can be placed on the conveyor belt to be transported out. Or at this time the forklift will wait to receive and move the goods.

Note: To optimize efficiency during the goods rotation process, it is necessary to arrange and distribute goods in a sequence consistent with the arrangement according to each cargo area or the bottom heavy goods.

Regarding structural characteristics, the automatic storage and retrieval system includes the following parts:

Depending on the installation requirements of each individual warehouse, the technical standards of the structural parts will be different. Contact INPA immediately via hotline (+84) 901 877 158 for more support and the most detailed advice!

When the warehouse needs a solution to optimize storage capacity along with a smart import-export process, strictly controlling each pallet position. And ASRS is the perfect choice. Below are the outstanding advantages when applying ASRS shelves in warehouse management:

ASRS racking system provides a solution for quickly picking up and transporting goods in and out of rows of shelves. Minimize interaction with people, eliminating the risk of collision completely thanks to the advantage of reducing the movement of forklifts deep into the racking system.

The integration of smart technology allows pallet access operations to not only ensure accurate results for each pallet location, but also in the fastest time in the safest way. That's why the ASRS solution becomes the ideal choice for warehouses:

Overall, this is a smart logistics management solution applied to large capacity warehouses that need optimal import and export control. However, the cost of installing an automatic storage and retrieval racking system will be higher than other storage methods. The reason is because businesses have to pay additional costs for smart robots and careful systems.

However, to help you consider applying automatic ASRS shelves, we suggest you the following key points to note:

When high demand means a large quantity of goods needs to be controlled and managed optimally, genuine ASRS shelves will help you solve most of the inadequacies in warehouse management.

See more: What is the Radio Shuttle Rack? Operating principle and Applications

Above are detailed information about the characteristics of ASRS shelves, hopefully they will help you better understand this smart shelf system. For any information that requires detailed consulting support, you can contact us directly via:

INPA VIETNAM COMPANY

Address: No. 19-21 Nguyen Van Troi, Ward 12, Phu Nhuan District, Ho Chi Minh City

Tel: (+84) 901.877.158

Email: info@inpa.com.vn

Website: inpa.com.vn