| Parameter | Description |

| Material | Iron and Steel |

| Brand | INPA |

| Feature | The Shuttle robot runs in and out of the shelf rails at a speed of 35m/min when storing goods, allowing the warehouse management process to take place with a high degree of accuracy, shortening processing time compared to normal manual operations. |

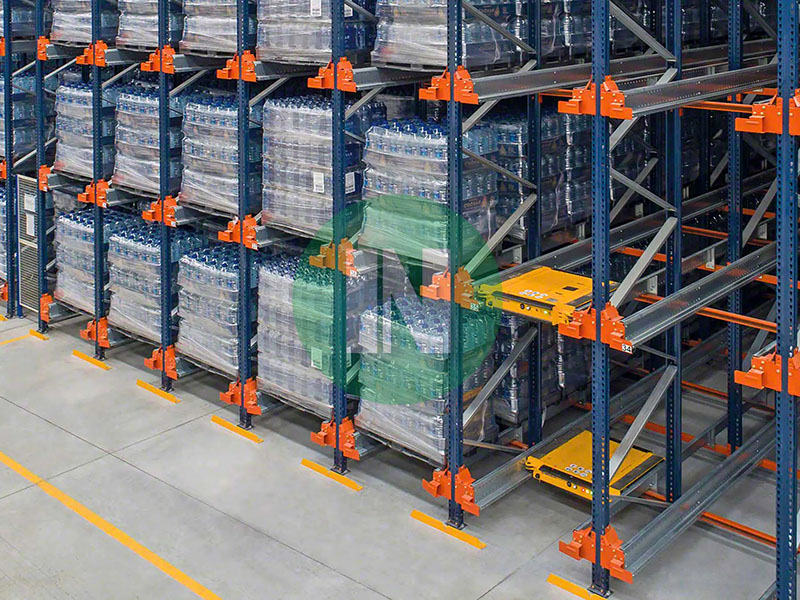

Radio Shuttle rack is a semi-automatic pallet racking system that allows deep storage and optimizes the process of importing and exporting goods quickly through robots integrated with smart sensor software. Refer to the article below to see how well INPA products meet your requirements!

Radio Shuttle rack is also known as Radio Shuttle shelf, Shuttle robot shelf or Shuttle rack. This is a deep storage shelf system, they are a set of adjacent rows of shelves that effectively optimize maximum capacity inside the warehouse.

A special feature of this shelf line is the intelligent application of the Shuttle robot solution that allows robots to enter/exit the shelf system to handle pallet loading and unloading. This advantage helps Shuttle robot shelves not only maximize efficiency in goods rotation. It also minimizes unnecessary collisions.

Using smart robots, the Shuttle rack system will be simulated with the following operating principles:

Loading goods: The robot is placed at the top of the guide rail, then the forklift will place the pallet containing the goods on the robot. After receiving control commands from the sensor software or remote device, the robot will move inside and proactively put the pallet into an empty position. Just like that, this process will continue until the rail fills the pallet.

Exporting goods: To export goods stored on the shelf rails, the robot, upon receiving the control command, will move inside and bring the goods to the top of the shelf until the forklift performs the operation of loading and unloading the goods from the shelf frame. Through the sensor, the robot recognizes that the forklift operation has been completed and will continue to load and unload goods. Just like that until the goods on each rail are taken out.

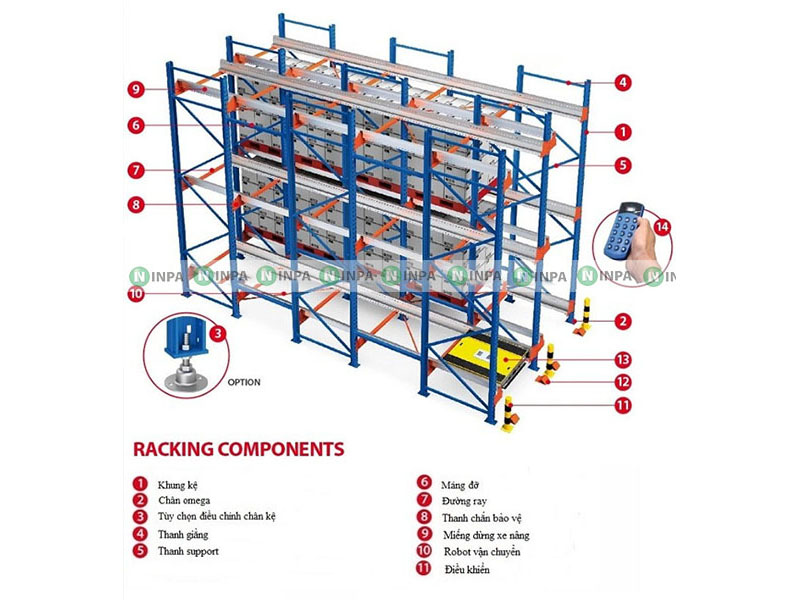

Basically, a set of robot Shuttle racks will be composed of the following details:

Smart warehouse application with INPA Shuttle rack robot shelf operation mechanism is selected as one of the optimal solutions, supporting warehouses to have good inventory control. As well as improve supply chain performance. Specifically:

In particular, the Shuttle INPA robot system helps investors conveniently navigate to automatic racking applications - automatic storage and retrieval systems ASRS or AGV without many customizations and expensive costs. red.

Thanks to the integration of smart technology applications, the Shuttle robot system closely manages and controls large-capacity warehouses. Some applications are considered the most optimal for Shuttle rack robots:

Storage applications through the Shuttle robot racking system are also quite popular because of the thick storage, ideal storage and accessibility capabilities suitable for the nature of the seafood, cooled or frozen food industry. However, for robots to be applied in cold storage, additional customized conditions will be needed to best suit each industry's characteristics as well as each specific warehouse space.

To receive more detailed advice, please contact INPA directly via hotline (+84) 901877 158!

In fact, the cost of operating the Radio Shuttle robot shelf system will be higher than other conventional shelves due to the need to invest in additional shuttle racks - Shuttle robots. However, to maximize your budget while still ensuring operational efficiency, you can contact INPA directly to receive advice on choosing the appropriate robot function for your warehouse requirements.

In addition, the number of robots will also be calculated and considered based on the actual situation. The size and characteristics of each warehouse are unique, and accurate quotes should be deployed after evaluating preliminary results from direct survey activities.

See more: Heavy duty racking systems | Racks meet European standards

INPA is pleased to support and accompany you. Please contact us for free warehouse survey support and the most accurate Shuttle robot shelf quote!

INPA VIETNAM COMPANY

Address: 19-21 Nguyen Van Troi, Ward 12, Phu Nhuan District, Ho Chi Minh City

Tel: (+) 901.877.158

Email: info@inpa.com.vn

Website: inpa.com.vn