In the FMCG (fast-moving consumer goods) sector, warehouse management is always a difficult problem due to the diversity of goods, large volumes and continuous import and export needs. Some notable challenges include:

FMCG warehouses often store large volumes of goods with diverse types, sizes, and particularly high turnover rates. Therefore, their racking systems must go beyond simply “holding” products, and instead meet the following requirements:

Selecting the right type of racking not only optimizes storage space but also boosts operational efficiency, cuts costs, and supports faster product movement. Below are the most popular racking systems in FMCG warehouses:

Heavy duty racking is a storage system with a very large load capacity, often used to store heavy, bulky pallets of goods such as large-boxed drinks, large quantities of dry food or raw materials. The thick steel structure, sturdy bolt connections and load capacity of several hundred to several thousand kg/floor help ensure absolute safety for goods. This is an ideal solution for large-scale FMCG warehouses that need to store huge amounts of goods and prioritize durability and high stability over many years of continuous operation.

Selective racking are the most popular type of shelves in the FMCG sector due to their flexibility and 100% accessibility to pallets of goods. Designed in single or double rows, the shelves allow for both FIFO (first in - first out) and LIFO (last in - first out) methods, suitable for products with short life cycles such as fresh food, milk, soft drinks or promotional goods that need to be imported and exported continuously. The big advantage is that it is easy to expand, the investment cost is reasonable, but the disadvantage is that the storage density is not too high due to the need to leave many aisles.

Double deep racks are designed with two rows of pallets stacked deep together, increasing storage density by about 30–40% compared to traditional Selective racks. This solution is especially useful for medium and large-scale warehouses that need to optimize space while maintaining relatively flexible access. However, to access the pallets at the back, a specialized forklift with a reach truck is required, which means higher equipment investment costs. This is a balanced choice between large storage capacity and moderate investment.

Drive-in racks have a “tunnel” structure that allows forklifts to move directly into the rack to retrieve pallets. This design helps to maximize the horizontal warehouse space, very suitable for homogeneous, large-quantity shipments that do not require frequent retrieval such as milk, beverages, and packaged foods. However, the ability to access each individual pallet is limited, not suitable for goods that need to be rotated continuously. Drive-in racks are often used in cold storage or long-term storage in the FMCG industry.

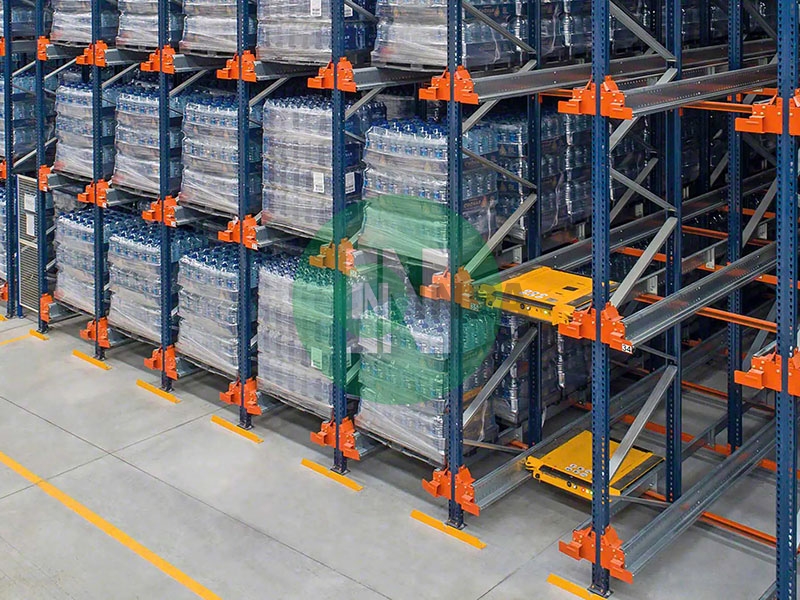

Radio shuttle racking is a modern semi-automatic storage system that uses self-propelled shuttle vehicles to move in rack slots to transport pallets. This solution significantly increases storage density, reduces loading and unloading time, and limits forklift collisions with goods. The system is especially suitable for FMCG warehouses with large output, requiring high turnover rates and modern inventory management processes. Although the initial investment cost is high, in the long run, Radio Shuttle racking helps save operating costs and increase circulation efficiency.

VNA racks are optimally designed for warehouses with very narrow aisles (only about 1.6-2m), combined with specialized forklifts for retrieval. This structure helps increase storage density by up to 40-50% compared to traditional shelf systems, while maximizing height space. This is an ideal solution for FMCG warehouses located in industrial parks and distribution centers, where space is very expensive. However, it is necessary to invest in specialized VNA forklifts and guide rail systems to ensure safe operation.

Flow racking operates based on the FIFO principle thanks to the inclined roller system, helping the pallet slide from the input end to the output end by gravity. This solution is especially effective for items with short shelf life such as yogurt, soft drinks, candy, etc. because it ensures continuous circulation and avoids expired inventory. In addition, this system also reduces picking time and limits forklift collisions, increasing overall operating efficiency for FMCG warehouses.

Cantilever racks are designed specifically for long, bulky goods such as plastic pipes, steel bars, industrial wood boards or large packaging rolls. In FMCG warehouses, this type of rack often plays a supporting role in storing large materials, packaging or accessories that cannot be placed on traditional pallets. The outstanding advantage is the ability to customize the length and height of the cantilever flexibly, easy to expand when demand increases, while still ensuring high safety.

Light-duty shelves are suitable for storing small packaged goods, accessories, consumables or display products. The compact design, easy to disassemble and move flexibly makes this type of shelf very popular in supermarket warehouses, FMCG stores or temporary storage areas. Although not able to bear heavy loads, the shelves still meet the needs of flexible and quick storage with low investment costs.

Medium-duty racking have a load capacity of 250-500kg/floor, and are a popular choice in small and medium-sized warehouses thanks to their durability, reasonable price, and ability to adapt to a variety of goods. This type of shelf is suitable for storing dry foods, cosmetics, household goods, fast-moving consumer goods, etc. in storage environments that require stability and the ability to rotate goods regularly. This is a well-balanced solution between load, cost, and space.

V-hole iron racks are the most flexible shelf line with the characteristics of being light, easy to disassemble, can change the size of the floors according to needs and especially have the lowest investment cost. Although they cannot withstand large loads, the shelves are still widely used to store light goods, components, accessories, documents or samples in small warehouses, FMCG retail stores. The big advantage is that it is easy to expand and rearrange the warehouse space at any time without spending much money or time.

Beyond the common racking systems, some businesses require special racking solutions tailored to unique production and storage needs. These systems are custom-designed to optimize space, load capacity, and safety.

Mezzanine racks are a shelf system integrated with an operating floor, allowing the warehouse height to be utilized to expand storage space and working area. With a smart design, the shelves not only help increase the usable area many times but can also be combined as an office, light production area or storage of bulky goods.

Mold racks are specially designed to store molds, machinery and heavy equipment in manufacturing plants. Each shelf level is often integrated with slide rails or a roller system to easily pull and push the mold without using too much force.

INPA Vietnam delivers comprehensive and professional racking solutions specifically for FMCG—an industry that demands high storage capacity, fast throughput, and accurate inventory control.

See more: Popular chemical warehouse shelving solutions today

With extensive experience in implementing large-scale FMCG warehouse projects nationwide, INPA Vietnam confidently positions itself as a strategic partner, helping businesses build modern, optimized, and sustainable warehouse systems.